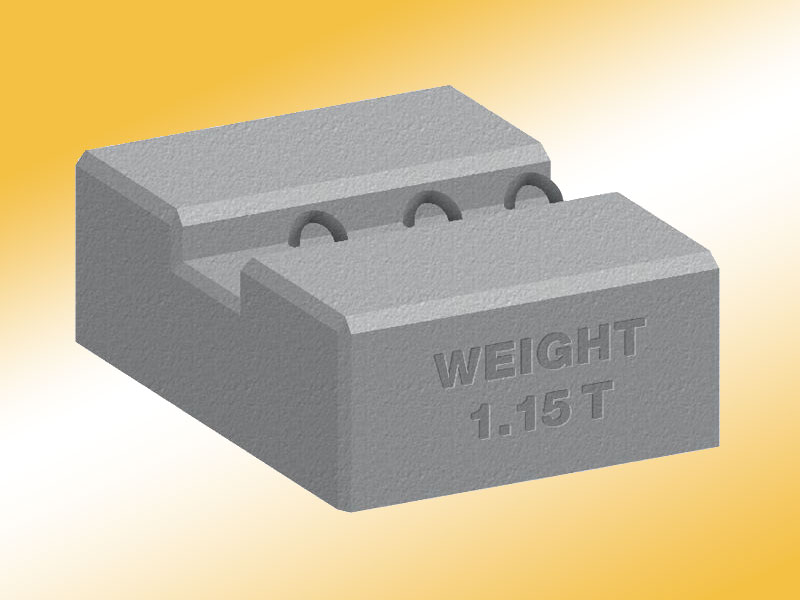

In the high-risk world of scaffolding, safety is paramount. Scaffolders face daily challenges that require not just skill and focus, but also robust systems that reduce risk and improve working conditions. One often-overlooked innovation making a significant impact is the use of precast concrete scaffold blocks.

Traditionally used to provide a ballast for temporary scaffolding structures, these ready-made concrete blocks have evolved into a safety-enhancing asset on construction sites. In this blog, we explore how precast scaffold blocks are contributing to improved health, safety, and overall working conditions for scaffolders across the UK.

Providing a Stable Foundation

One of the core benefits of precast concrete scaffold blocks is the improved base stability they offer.

- Even Weight Distribution – Unlike improvised bases (i.e. timber offcuts or uneven soil), precast blocks offer consistent weight distribution, reducing the risk of scaffold movement or settlement.

- Less Ground Preparation Required – This reduces manual groundwork, which can be strenuous or hazardous on rough terrain.

- Improved Load Bearing – High-quality precast blocks are engineered to support heavy loads, ensuring scaffolds remain firm under working conditions.

By creating a secure foundation, these scaffold blocks minimise the likelihood of tipping, collapse, or tilting—all common causes of scaffolding accidents.

Reducing Manual Handling Injuries

Manual handling is a major source of injury in the construction sector, particularly among scaffolders, who routinely lift and position heavy components.

- Standardised Sizes and Lifting Points – Precast blocks are manufactured with predictable dimensions and can come with built-in lifting loop, allowing for mechanical handling.

- Ergonomic Handling – Unlike makeshift or uneven site materials, precast units are designed for safe lifting by mechanical handling, reducing manual handling injuries as the crane takes the strain.

By minimising manual strain, these blocks contribute to long-term occupational health for scaffolders—particularly important in an aging workforce.

Faster, Safer Installations

Scaffolders often work to tight deadlines, and speed can sometimes compromise safety. Precast scaffold blocks help mitigate this risk.

- Time-Saving Deployment – The uniformity of precast units allows for quicker installation compared to site-built or ad hoc bases, reducing time spent on-site and exposure to hazards.

- Improved Worksite Organisation – With clearly defined, consistent base locations, scaffolding can be set up in a more organised and controlled manner—reducing tripping hazards, misalignment, and accidents during assembly.

Speed with safety is the ultimate goal, and precast blocks help scaffolders achieve both.

Weather Resistance and Durability

Outdoor construction work in the UK is often affected by extreme heat, wet or icy conditions. Precast scaffold blocks are engineered to handle these extremes:

- Non-Degradable Surface – Unlike timber or soil supports that can rot or degrade in the rain, concrete remains solid and slip resistant.

- Low Maintenance – Once placed, they require little adjustment, reducing the need for scaffolders to re-enter hazardous zones for corrections.

- Resistant to Frost Heave – Properly manufactured precast blocks are less susceptible to frost-related ground movement, maintaining scaffold alignment during winter months.

- No Special Protection Measures – Are required against damage from sunlight or the heat.

This durability adds another layer of protection during unpredictable weather—a key concern for site safety officers.

Minimising On-Site Risk Through Off-Site Manufacturing

One of the broader health and safety advantages is the off-site production process:

- Controlled Manufacturing Conditions – Precast blocks are made in factory-controlled environments, ensuring higher quality, fewer defects, and better consistency than site-cast alternatives. If buying from Elite Precast Concrete, they are compliant with ISO 9001, ISO 14001 and ISO 45001 giving extra confidence.

- Reduces On-Site Cutting or Casting – Minimising concrete work on-site reduces noise, dust, and exposure to silica—contributing to better respiratory health and site cleanliness.

This shift to off-site production reflects a growing trend in modern methods of construction: moving hazardous processes away from the worksite wherever possible.

Supporting Compliance with Safety Regulations

The use of precast scaffold blocks helps companies align with several key health and safety standards, including:

- HSE Guidelines on Safe Scaffolding Practices

- Manual Handling Operations Regulations (MHOR)

- CDM Regulations 2015 (Construction Design and Management)

By reducing on-site variability and risks, these blocks help employers meet legal duties and demonstrate proactive safety planning.

Conclusion: Small Innovation, Big Impact

Precast concrete scaffold blocks may seem like a minor component in the grand scheme of a construction project—but for scaffolders, they represent a significant step forward in health and safety. From improving site stability and reducing injury risk, to saving time and ensuring regulatory compliance, these scaffold blocks are proving to be a reliable ally on modern job sites.

As the construction industry continues to prioritise worker welfare, the adoption of such practical, safety-enhancing tools is growing. Sometimes, it’s the solid, simple solutions—like a well-made concrete block—that make the biggest difference on the ground.

If you’re a site manager, scaffolder, or safety officer interested in safer scaffolding practices, get in touch on 01952 588885 or email sales@eliteprecast.co.uk