Temporary Vertical Concrete Barriers (TVCBs)

Defence-Grade Security Solutions

Our Temporary Vertical Concrete Barriers (TVCBs) are engineered to deliver uncompromising protection in defence environments—ranging from military bases to command zones, high-risk perimeter control points, and rapid-response security lockdowns.

Why Defence Teams Trust Our TVCBs for Hostile Vehicle Mitigation (HVM)

- Designed to repel vehicle intrusion attempts—including ram-raiding and high-speed attacks—these barriers create a fortified perimeter that safeguards both personnel and strategic assets.

- Robust and Durable Construction – Cast from 50 N/mm² high-strength concrete, TVCBs meet rigorous standards including EN 1317 for temporary motorway restraint systems.

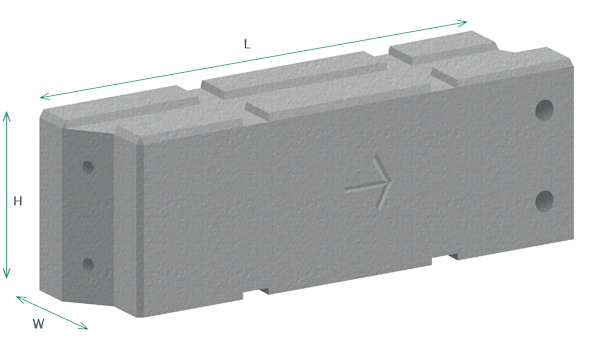

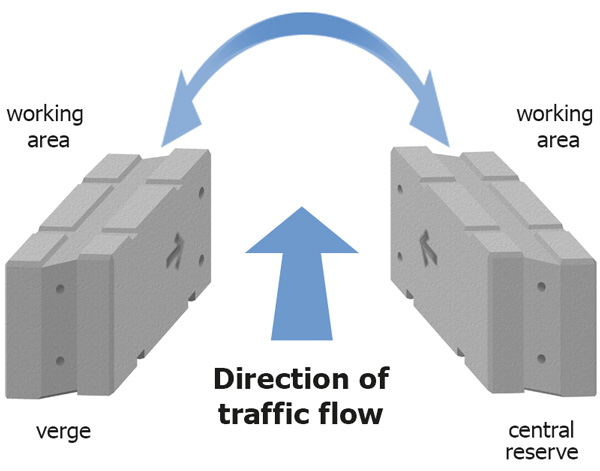

- Modular & Rapid Deployment – Featuring secure scarf-joint connections fastened with M24 high-tensile bolts, TVCBs lock into strong, continuous barricades deployable in any field scenario.

- Operationally Flexible – Lightweight design (approx. 2.5 tonnes per unit) allows rapid reconfiguration for evolving tactical requirements. Ideal for establishing temporary zone lockdowns or redirecting access routes.

- Built to Withstand Extremes – Withstands harsh weather, physical abuse, and repeated use—safeguarding long-term installations with minimal maintenance.

- Cost-Efficient Compared to Permanent Infrastructure – Delivers immediate, deployable security without the expense or permanence of fixed construction.

Product Choice

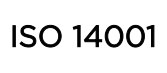

| TCVB Block Code | Product Drawing | Overall length (mm) |

Modular length (mm) |

W x H (mm) | Weight |

| V28 | 3150 | 3000 | 450 x 800 | 2500kg | |

| V29 | 3075 | 3000 | 450 x 800 | 1700kg | |

| V30 | 3075 | 3000 | 450 x 800 | 1700kg | |

| V41 | 2155 | 2000 | 450 x 800 | 1630kg |

Key Technical Highlights

| Features | Specification / Benefit |

| Concrete Strength | 50 N/mm² high-grade—engineered for tactical resilience |

| Standard Unit Weight | Approx. 2,500 kg per module; also available in lighter variants |

| Dimensions (Typical) | ~3,000 mm length × 800 mm width × 450 mm height |

| Assembly Method | Scarf joint locked with M24 high tensile bolts |

| Standards & Certification | Compliant with EN 1317; produced under ISO-certified systems |

Defence Applications & Use Cases

Base Perimeter Defence

Rapidly cordon off critical zones and create temporary fortifications without ground excavation.

Checkpoint & Gate-Level Security

Integrate barriers into site access points to delay or deter unauthorised vehicles.

Event and Drill Scenarios

Provide secure separation during live exercises, high-profile visits, or crowd management operations.

Flexible Internal Zoning

Establish controlled internal buffers during emergencies, lockdowns, or threat responses.

Deployment Advantages

- Quick Turnaround – Delivered from stock, ready for immediate deployment.

- No Groundworks Required – Ready to install on any surface, perfect for leased or fragile domains.

- Relocatable – Disassembly and redeployment are easy for dynamic defence environments.

- Made in the UK – Ensures consistent quality, shorter lead times, and simplified logistics.

Elite Precast TVCBs offer ultimate defence-grade protection through robust, modular, and rapidly deployable concrete barriers that excel in hostile vehicle deterrence, perimeter control, and dynamic security operations. Compliant with stringent standards, designed for durability, and available for fast deployment—these barriers are the trusted choice for modern defence and security teams.

Units are connected together at the scarf joint, using M24 diameter high-tensile bolts. Units can also be fixed to the carriageway if required, by use of anchor plates bolted to the underside of the barriers.

Next Steps

- Request Technical Drawings and Datasheets to assess integration requirements.

- Specify Your Threat Level and Deployment Environment to tailor barrier configuration.

- Contact the Elite team for pricing, delivery options, or bespoke solutions.

Important note:

It is the customer’s responsibility to ensure appropriate structural checks are carried out before any precast concrete products are installed.

TVCB’s should only be lifted/off-loaded from above using the central 5 tonne pin anchor and clutch or the four M24 threaded sockets and lifting loops.

Prior to lifting older / pre-used blocks check the lifting pin for wear / corrosion and check the block for cracks. If the block is cracked or the pin is worn it could fail when being lifted.